Spring Loaded & Pilot Operated Pressure Relief Valve ASME Section I and VIII / API

Made in USA & CANADA

PRODUCT

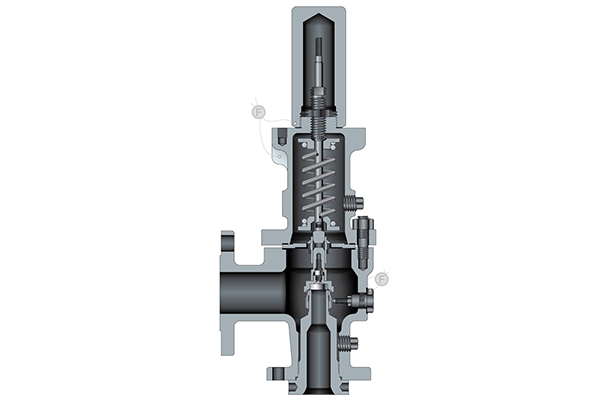

2600/2600L Series

Pressure Relief Valves

Size: 1” x 2” to 20” x 24”

Orifice Areas: D to Z

Set Pressure Ranges: 15 to 6000 psig (1.0 to 413 barg)

Temperature Ranges: -320 to 1500°F (-195 to 815°C)

Flange Classes: 150# – 2500#

Suitable for: Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature Alloy Steels, Monel, Hastelloy C, Duplex ,NACE Compliant Materials

2700 Series

Pressure Relief Valves

Size: 1/2” x 1” to 1-1/2” x 2-1/2”

Orifice Areas: C to G

Set Pressure Ranges: 15 to 6500 psig (1.0 to 413 barg)

Temperature Ranges: -320 to 750°F (-195 to 399°C)

Flange Classes: 150# – 2500#

Suitable for: Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature Alloy Steels, Monel, Hastelloy C, Duplex ,NACE Compliant Materials

3800 Pilot Operated Series

Process Valve

Size: 1” x 2” to 12” x 16”

Orifice Areas: D to T

Set Pressure Ranges: 15 to 6170 psig (1.0 to 425 barg)

Temperature Ranges: -320 to 500°F (-195 to 260°C)

Flange Classes: 150# – 2500#

Suitable for: Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature Alloy Steels, Monel, Hastelloy C, Duplex ,NACE Compliant Materials

Accessories: Dual Pilot, Reverse Flow Preventer, Field Test Connection, Remote Depressurizing, Auxiliary Filters, Consult Catalog for additional accessories

SMART PRV

The Farris’ Smart PRV features a 2600 Series Pressure Relief Valve (PRV) Equipped with a Fisher 4320 Wireless Position Monitor.

FEATURES & BENEFITS

A high stable flow coefficient

• Greater strength to resist possible discharge piping strains

• Easy maintenance

• Long service life

• Nozzle design

• WirelessHART Protocol

• Integrates into plants with existing Emerson Wireless Infrastructure

• Orifice Sizes D through U

• Retrofits available for installed 2600 Series valves

6400 Series

Steam Safety Valve

Designed with the user in mind, Series 6400 and 6600 safety valves represent the most advanced technology in valves designed for use in intermediate power boiler and organic fluid vaporizer service.

Size: 1” x 2” to 4” x 6”

Orifice Areas: D to P

Set Pressure Ranges: 15 to 1500 psig (1.0 to 103barg)

Temperature Ranges: -20 to 1000°F (-29 to 538°C)

Flange Classes: 150# – 1500#

Materials of Construction: Carbon Steel, Stainless Steel, Chrome-Moly

4200 Series

Steam Safety Valve

The 4200 Series was designed to meet your requirements for a dependable, cost effective, high capacity boiler safety valve.

Size: 1” x 1/4” x 1-1/2” to 6” x 8”

Orifice Areas: F to Q

Set Pressure Ranges: 15 to 1000 psig (1.0 to 68.9 barg)

Temperature Ranges: -20 to 1000°F (538°C)

Flange Classes: 150# – 600#

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature, Alloy Steels, Chrome-Moly

2400 Series

Pressure Relief Valves

A high performance direct spring loaded pressure relief valve with a soft seat design to provide reliable overpressure protection.

Size: 1/2” x 3/4” to 1” x 1”

Orifice Areas: B to E

Set Pressure Ranges: 20 to 2,000 psig (1.38 to 137.9 barg)

Temperature Ranges: -450 to 550°F (-268 to 288°C)

Seat Materials: Elastomer, Plastic

Suitable for: Air, Gas, Vapor

Materials of Construction: Carbon Steel, Stainless Steel, Brass/Bronze