API Ball Valve & Fire Safe Ball Valve

Made in ITALY

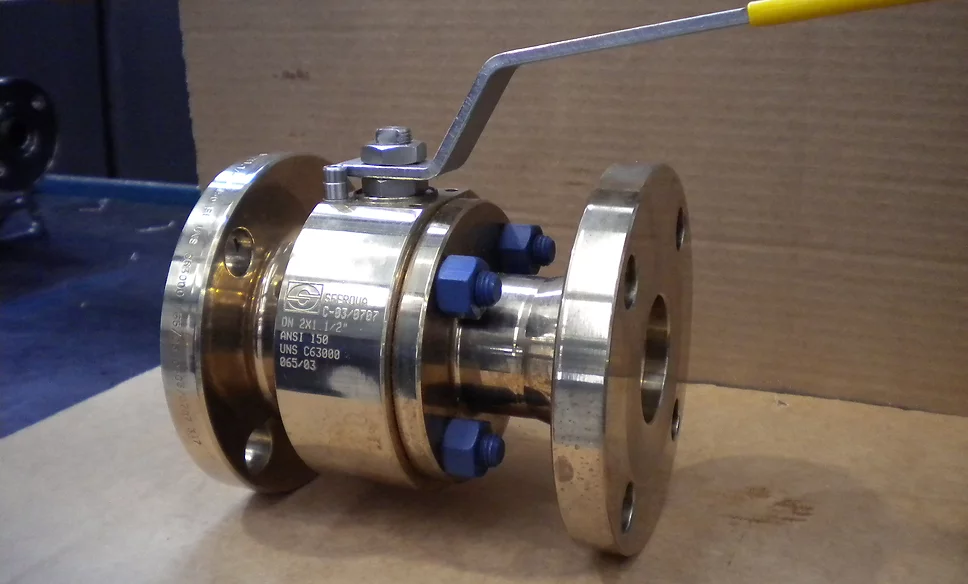

TQ2

Floating ball valvesFloating ball valves, construction to ASME B16.34 – ASME VIII Div.II, 2 piece bolted body, split body, side entry, flanged RF/RTJ to ANSI B16.5, face to face to ANSI B16.10, full/reduced bore, ISO (5211) top work standardized for actuation, seat leakage rate to ISO 5208 Rate A, fire safe certified to BS 6755 Part II-API 607-API6FA, antistatic & blow out proof stem.

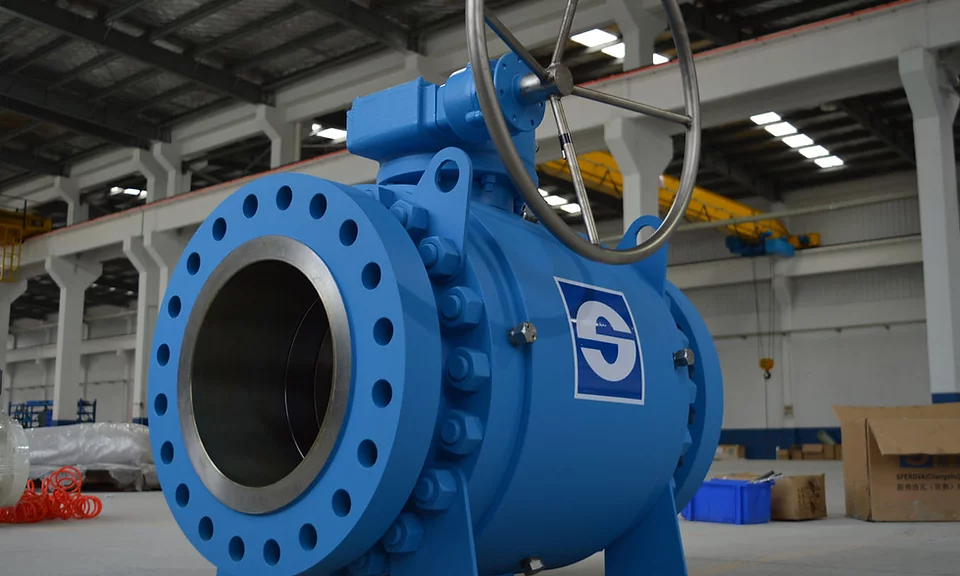

TM2 / TM3

Trunnion mounted ball valvesTrunnion mounted ball valves, construction to ASME B16.34 - API6D, 2/3 piece bolted body, or fully welled body, split body, side entry, double block & bleed, flanged RF/RTJ to ANSI B16.5, face to face to ANSI B16.10, full/reduced bore, ISO (5211) top work standardized for actuation, seat leakage rate to ISO 5208 Rate A, fire safe certified to BS 6755 Part II-API 607-API6FA, antistatic & blow out proof stem, self relieving seats, vent & drain.

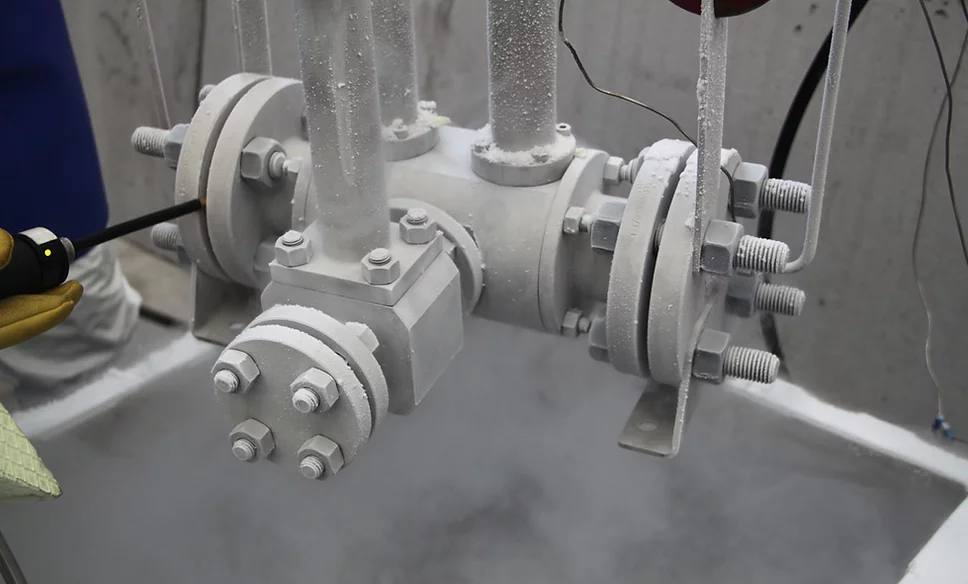

CRY Type

TQ2-CRY Floating ball valvesTM2-CRY /TM3-CRY Trunnion mounted ball valves

TQ2-CRY Floating ball valves, construction to ASME B16.34 – ASME VIII Div.II, 2 piece bolted body, split body, side entry, flanged RF/RTJ to ANSI B16.5, face to face to ANSI B16.10, full/ reduced bore, ISO (5211) top work standardized for actuation, seat leakage rate to ISO 5208 Rate A, fire safe certified to BS 6755 Part II-API 607-API6FA, antistatic & blow out proof stem. Extended bonnet, materials and seals suitable for cryogenic application @ -196°C.

TM2-CRY /TM3-CRY Trunnion mounted ball valves, construction to ASME B16.34-API6D, 2/3 piece bolted body, split body,side entry, double block & bleed, flanged RF/RTJ to ANSI B16.5, face to face to ANSI B16.10, full/ reduced bore, ISO (5211) top work standardized for actuation, seat leakage rate to ISO 5208 Rate A, fire safe certified to BS 6755 Part II-API 607-API6FA, antistatic & blow out proof stem, self-relieving seats, vent & drain.

TQT / TQT - INT

Floating ball valvesFloating ball valves, constructionto ISO 17292, one piece threaded body joint, end entry, with screwed GAS ends to BSPP-UNI 338 – with screwed NPT F ends to ASME B1.20.1 - SW ends to ASME B16.11 or ‘-INT’ version complete with no. 2 long integral nipples (L=100mm/each) PE or BW to ASME B16.25, full bore, face to face to our std., ISO (5211) top work standardized for actuation, seat leakage rate to ISO 5208 Rate A, antistatic &blow out proof stem.